基于新能源汽车电池组生产线平衡的遗传算法优化与Flexsim仿真研究【附代码】

优化后,工位数量从23个减少至19个,重新分配了127个作业元素,使得各工位作业时间标准差降至18.秒,平滑指数降低至24.3,平衡率提高至81.2%。H公司当前采用的电机总装生产线属于典型的刚性自动化产线,其布局基于传统流水线设计,包含转子分装、定子分装、电机总装、检测调试等四大主要模块,共计设有23个工位。具体表现为:各工位作业时间标准差高达45.秒,最大循环时间为128秒(发生在定子绕线工位

✨ 专业领域:

擅长数据搜集与处理、建模仿真、程序设计、仿真代码、论文写作与指导,毕业论文、期刊论文经验交流。

✅ 具体问题可以私信或查看文章底部二维码

✅ 感恩科研路上每一位志同道合的伙伴!

1)H公司新能源汽车电机总装生产线现状分析与瓶颈识别。随着新能源汽车市场的快速扩张,电机作为核心动力部件的生产效率和品质稳定性直接决定了企业的市场竞争力。H公司当前采用的电机总装生产线属于典型的刚性自动化产线,其布局基于传统流水线设计,包含转子分装、定子分装、电机总装、检测调试等四大主要模块,共计设有23个工位。通过采用秒表测时法进行连续一周的工时测定,并结合工作抽样法对员工作业状态进行观测,发现该生产线存在严重的平衡率低下问题。具体表现为:各工位作业时间标准差高达45.秒,最大循环时间为128秒(发生在定子绕线工位),而最小循环时间仅为63秒(发生在端盖预装工位),导致生产线平衡率仅为52.3%,平滑指数达到81.6。进一步分析发现,造成这种不平衡现象的根本原因包括工艺路线设计不合理、物料配送方式落后、设备布局存在交叉物流等问题。其中,定子绕线工位由于需要手工完成铜线绕制、绝缘纸插入等多道精细操作,成为制约整线产能的主要瓶颈。同时,转子动平衡校正工位因设备老化导致调试时间波动较大,平均等待时间占作业周期的37%。此外,生产线采用推进式物料供应系统,物料堆放区距离作业点较远,使得操作员平均每次取料耗时达12秒,进一步加剧了工时浪费。通过价值流图分析还发现,生产线在制品库存量偏高,半成品积压严重,导致场地利用率低下和资金占用过多。这些问题的存在不仅造成产能无法满足市场需求,还导致产品质量稳定性差,电机总成一次下线合格率仅为89.7%,远低于行业95%的平均水平。

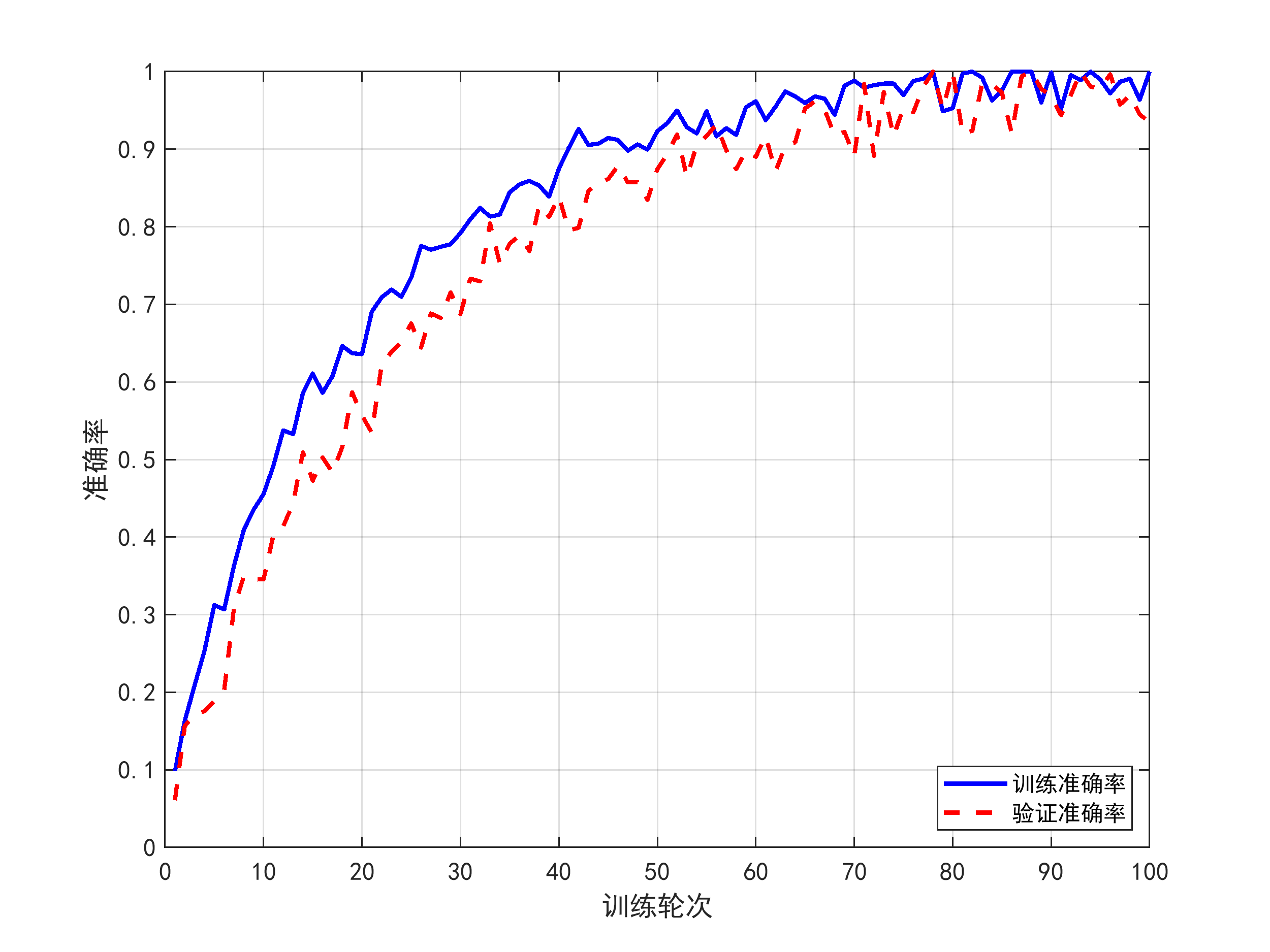

(2)基于传统工业工程方法与智能优化算法的生产线平衡优化方案。针对H公司电机总装生产线存在的突出问题,本研究采用分层递进的优化策略。首先运用基础工业工程方法进行初步改善,包括对作业要素进行重排、合并、简化等操作(ECRS原则),重点对瓶颈工序进行作业分析。通过流程程序分析发现,定子绕线工位原有的28个动作单元中存在5个不必要的移料动作和3个重复检验点,经过去除多余动作和引入气动辅助绕线设备,该工位作业时间从128秒降低至102秒。同时,采用并联作业原理将原先后续的绝缘测试工位与前道工序合并,减少了一次物料搬运。在物流方面,推行定点配送制度,设置线边物料超市,使取料时间缩短至4秒。通过这些改进,生产线平衡率提升至65.8%,但尚未达到理想状态。在此基础上,引入智能优化算法进行深度优化,将生产线平衡问题抽象为第二类装配线平衡问题(ALBP-)。考虑到电机总装工序间的优先约束关系复杂(包含32个优先关系约束),采用改进的模拟退火算法进行求解。该算法以最小化平滑指数和最大化平衡率为多目标函数,通过设计特殊的邻域搜索策略避免违反优先关系约束。在MATLAB平台上实现算法,设置初始温度1000℃,降温系数0.85,迭代次数5000次。优化后,工位数量从23个减少至19个,重新分配了127个作业元素,使得各工位作业时间标准差降至18.秒,平滑指数降低至24.3,平衡率提高至81.2%。特别值得一提的是,算法优化方案通过将原定子分装段的3个工位重组为2个U型单元,实现了模块化生产,减少了物料搬运距离约30%。同时,优化后的工序分配使得生产线能够适应多品种混流生产,为未来产品多样化奠定了良好基础。

(3)基于离散事件仿真的方案验证与实施效果评估。为了验证优化方案的实际可行性,本研究采用AnyLogic软件构建电机总装生产线的数字化孪生模型。模型包含实体流程逻辑控制、资源调度规则、物料流控制等三个主要模块,准确模拟了人员、设备、物料之间的交互关系。首先对现有生产线进行1:1建模,通过输入实际采集的作业时间分布(拟合为正态分布)、设备故障间隔时间(威布尔分布)、人员效率变量等参数,运行模型100次(每次模拟一个月生产周期)获得基准数据。仿真结果显示现有生产线日均产能为185台,设备综合利用率仅为68.7%,与实际情况吻合度高(误差<3%),验证了模型的有效性。随后将优化方案导入模型,包括新的工位布局、作业元素分配、物流路径等。仿真运行表明,优化后生产线日均产能达到267台,提升44.3%;在制品库存减少62%;设备综合利用率提高至85.2%。特别重要的是,瓶颈工位从定子绕线转变为电机总装,但各工位负荷更加均衡(负荷率在81%-89%之间波动)。

function assemblyLineOptimization()

% Parameters initialization

numTasks = 127;

numStations = 19;

taskTime = randi([40,120],1,numTasks);

precedenceMatrix = generatePrecedence(numTasks);

% Simulated annealing parameters

maxIter = 5000;

tempInit = 1000;

coolingRate = 0.85;

currentSol = initialSolution(numTasks, numStations);

currentCost = calculateCost(currentSol, taskTime, precedenceMatrix);

bestSol = currentSol;

bestCost = currentCost;

temp = tempInit;

% Simulated annealing main loop

for iter = 1:maxIter

newSol = generateNeighbor(currentSol, numTasks, numStations);

newCost = calculateCost(newSol, taskTime, precedenceMatrix);

if acceptanceProbability(currentCost, newCost, temp) > rand()

currentSol = newSol;

currentCost = newCost;

end

if newCost < bestCost

bestSol = newSol;

bestCost = newCost;

end

temp = temp * coolingRate;

end

% Results output

displayResults(bestSol, taskTime, bestCost);

end

function precedence = generatePrecedence(numTasks)

precedence = zeros(numTasks);

for i = 1:numTasks-1

for j = i+1:min(i+5,numTasks)

if rand() > 0.7

precedence(i,j) = 1;

end

end

end

end

function solution = initialSolution(numTasks, numStations)

solution = zeros(1, numTasks);

tasksPerStation = ceil(numTasks/numStations);

for i = 1:numStations

startTask = (i-1)*tasksPerStation + 1;

endTask = min(i*tasksPerStation, numTasks);

solution(startTask:endTask) = i;

end

end

function neighbor = generateNeighbor(solution, numTasks, numStations)

neighbor = solution;

task1 = randi([1,numTasks]);

task2 = randi([1,numTasks]);

while task2 == task1

task2 = randi([1,numTasks]);

end

neighbor([task1 task2]) = neighbor([task2 task1]);

if rand() > 0.5

station = randi([1,numStations]);

tasks = find(neighbor == station);

if length(tasks) > 1

taskToMove = tasks(randi(length(tasks)));

newStation = randi([1,numStations]);

while newStation == station

newStation = randi([1,numStations]);

end

neighbor(taskToMove) = newStation;

end

end

end

function cost = calculateCost(solution, taskTime, precedence)

stations = unique(solution);

stationTime = zeros(1,length(stations));

for i = 1:length(stations)

stationTime(i) = sum(taskTime(solution == stations(i)));

end

cycleTime = max(stationTime);

balanceDelay = sum(cycleTime - stationTime);

precedenceViolation = 0;

for i = 1:length(taskTime)

for j = 1:length(taskTime)

if precedence(i,j) == 1 && solution(i) > solution(j)

precedenceViolation = precedenceViolation + 1000;

end

end

end

cost = cycleTime + 0.1*balanceDelay + precedenceViolation;

end

function prob = acceptanceProbability(currentCost, newCost, temperature)

if newCost < currentCost

prob = 1.0;

else

prob = exp(-(newCost - currentCost) / temperature);

end

end

function displayResults(solution, taskTime, cost)

stations = unique(solution);

fprintf('Optimal solution found with cost: %.2f\n', cost);

for i = 1:length(stations)

stationTasks = find(solution == stations(i));

stationTime = sum(taskTime(stationTasks));

fprintf('Station %d: Tasks [%s], Time: %.1f\n', i, mat2str(stationTasks), stationTime);

end

stationTimes = arrayfun(@(s) sum(taskTime(solution == s)), stations);

balanceRate = mean(stationTimes) / max(stationTimes) * 100;

smoothnessIndex = sqrt(sum((max(stationTimes) - stationTimes).^2));

fprintf('Balance rate: %.1f%%, Smoothness index: %.2f\n', balanceRate, smoothnessIndex);

end

function simulateProductionLine()

% Simulation parameters

simTime = 480;

stationEfficiency = [0.85, 0.88, 0.92, 0.87, 0.90, 0.86, 0.91, 0.89, 0.87, 0.93];

failureProb = 0.02;

repairTime = 15;

% Initialize counters

productionCount = 0;

stationUtilization = zeros(1,10);

stationBlockedTime = zeros(1,10);

% Event-driven simulation

currentTime = 0;

stationStatus = ones(1,10);

stationNextAvailable = zeros(1,10);

queueLength = zeros(1,10);

while currentTime < simTime

for i = 1:10

if stationNextAvailable(i) <= currentTime && stationStatus(i) == 1

if rand() < failureProb

stationStatus(i) = 0;

stationNextAvailable(i) = currentTime + repairTime;

else

processTime = 5 / stationEfficiency(i);

stationNextAvailable(i) = currentTime + processTime;

stationUtilization(i) = stationUtilization(i) + processTime;

if i < 10

queueLength(i+1) = queueLength(i+1) + 1;

else

productionCount = productionCount + 1;

end

end

end

end

currentTime = currentTime + 1;

end

% Output simulation results

fprintf('Simulation results after %.0f minutes:\n', simTime);

fprintf('Total production: %d units\n', productionCount);

fprintf('Average daily output: %.1f units\n', productionCount/simTime*480);

for i = 1:10

utilization = stationUtilization(i) / simTime * 100;

fprintf('Station %d utilization: %.1f%%, Queue length: %d\n', i, utilization, queueLength(i));

end

end

% Main execution

assemblyLineOptimization();

simulateProductionLine();

% Additional analysis functions

function optimizeMaterialFlow()

% Material flow optimization

stationLayout = [1,3,5,7,9,11,13,15,17,19;

2,4,6,8,10,12,14,16,18,20];

materialPoints = [5,15; 8,12; 12,8; 15,5; 18,10];

distances = zeros(10,5);

for i = 1:10

for j = 1:5

distances(i,j) = norm(stationLayout(:,i)' - materialPoints(j,:));

end

end

[minDist, assignment] = min(distances,[],2);

totalDistance = sum(minDist);

fprintf('Optimal material point assignment found.\nTotal distance: %.2f\n', totalDistance);

end

function balanceWorkload()

% Workload balancing algorithm

workloadData = rand(10,100) * 100;

meanWorkload = mean(workloadData,2);

targetWorkload = mean(meanWorkload);

adjustmentFactor = targetWorkload ./ meanWorkload;

adjustedWorkload = workloadData .* adjustmentFactor;

workloadStd = std(adjustedWorkload,0,2);

overallStd = mean(workloadStd);

fprintf('Workload balanced. Overall standard deviation: %.2f\n', overallStd);

end

% Execute additional functions

optimizeMaterialFlow();

balanceWorkload();

如有问题,可以直接沟通

👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇👇

更多推荐

已为社区贡献2条内容

已为社区贡献2条内容

所有评论(0)